Machine elements

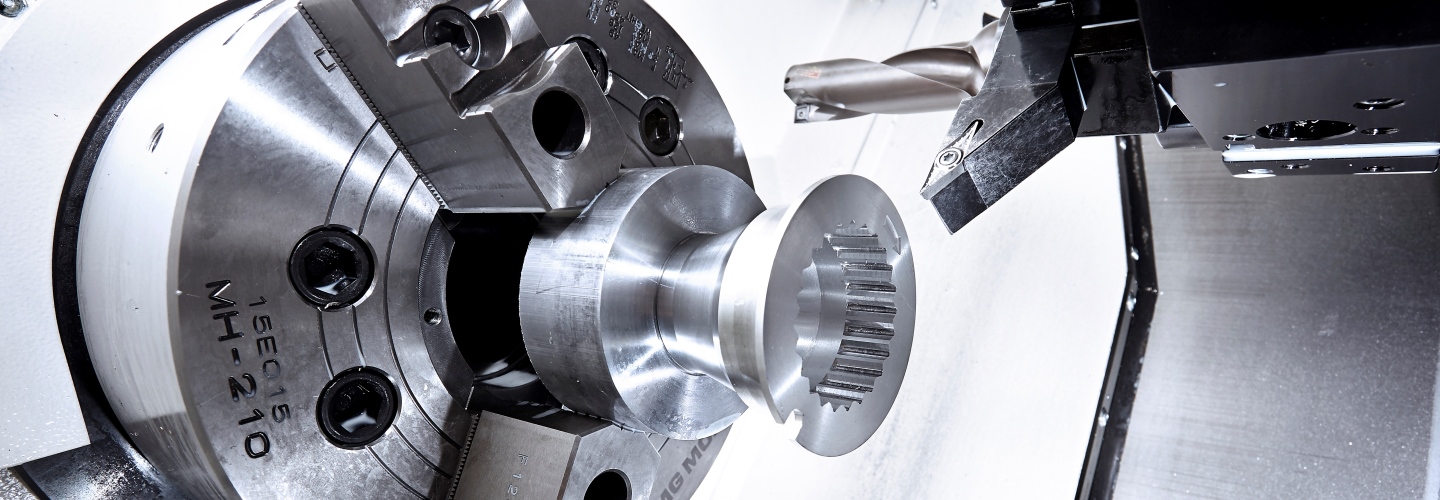

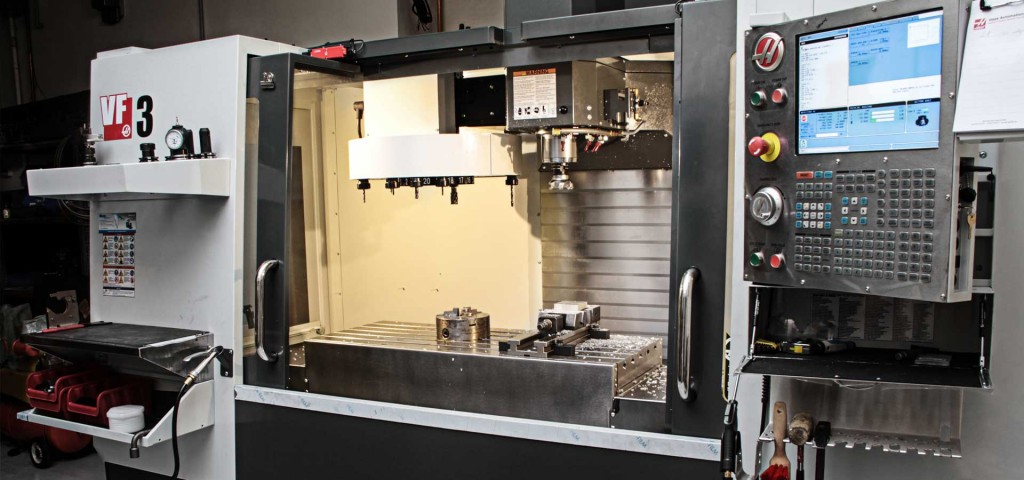

In Kamilena we use CNC machines for chip machining and injection molding

machines for the production of plastic components. We own the latest

devices for metalworking with CNC technology. In our plant there is a CNC milling and turning centre as well as well-equipped welding centre. We produce both single elements and large series in optimally short time. Drive shafts, pulleys, flanges, screws, sleeves, cones, screw caps, couplings, connection pipes, reductions, tap screws, punches, columns, ejectors, ejectors (knock-outs), shafts (cylinders, rollers), bushings, rings, lids, pistons, piston rods, pegs (pins) and many other details- this is only a small part of our business profile. Wide and modern machine park allows us to maketechnically complex machine parts while maintaining high accuracy.

MACHINE PARk

Because of modern and hundred percent efficient CNC lathes and milling machines, we make mold cavities for injection molds; blanking dies and dies for sheet metal. We manufacture setting and checking devices, mounting brackets, rotors of small rotating machines and auxiliary tools. Flat-surface, cylindrical and internal grinders allow us to obtain a smooth surface with low roughness and at the same time keep dimensions within limits of tolerance. It is an after-machining which requires precision and experienced staff. Our machines and machine tools equipped with measurement systems ensure repeatability from the first to the last piece. However, before the elements are delivered to our customer, they must pass quality control. We also offer an option of folding ready mechanisms from components produced by us and manufacturing machine frame and housing. In the welding room we weld frames using the TIG method in the acetylene gas shield or MMA method.

Because of modern and hundred percent efficient CNC lathes and milling machines, we make mold cavities for injection molds; blanking dies and dies for sheet metal. We manufacture setting and checking devices, mounting brackets, rotors of small rotating machines and auxiliary tools. Flat-surface, cylindrical and internal grinders allow us to obtain a smooth surface with low roughness and at the same time keep dimensions within limits of tolerance. It is an after-machining which requires precision and experienced staff. Our machines and machine tools equipped with measurement systems ensure repeatability from the first to the last piece. However, before the elements are delivered to our customer, they must pass quality control. We also offer an option of folding ready mechanisms from components produced by us and manufacturing machine frame and housing. In the welding room we weld frames using the TIG method in the acetylene gas shield or MMA method.

PL

PL  EN

EN