CNC milling and turning

CNC TURNING AND MILLING

In our plan in Lodz we manufacture parts with high precision and complexity with the use of CNC milling machines and lathes. We specialize in serial turning of elements from 16mm diameter using driven tools and Y axis. We are able to make even difficult elements from one mounting only which significantly shortens the processing time and reduces costs to a minimum. By investing in the latest machines available on the market, we try to meet the most demanding requirements of our customers from aviation, automotive, medical and other industries.

The details made by us are checked using measuring instruments from renowned companies such as Mitutoyo or VIS. For serial orders, measurements are performed in two stages. The first stage are the measurement tests for each manufactured part. The second stage is a control measurement for every 10th piece. This ensures the highest quality of services.

We turn series on DMG MORI lathes equipped with driven tools and Y axis, which allows making grooves for keys, radial holes, threads and milling from a single mounting. The machines are equipped with direct measuring lines and very fast drives, which in combination with the stiffness of the machine ensures

Highest precision in the shortest time at the lowest price.

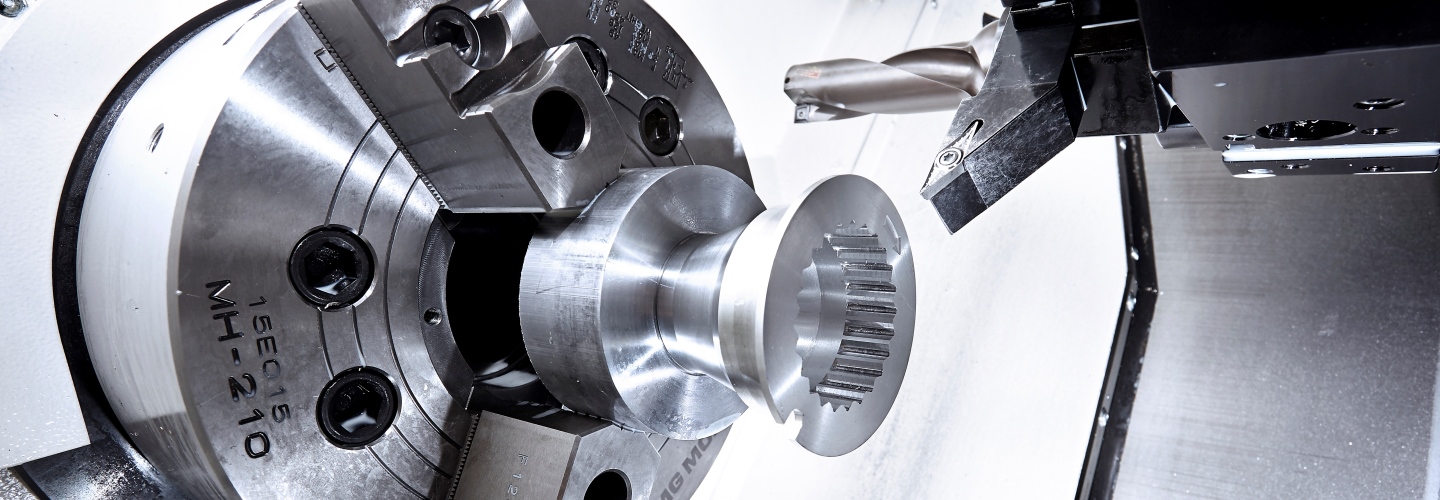

CNC TURNING

CNC turning is one of the most popular and most modern types of chip machining of materials. The turning process uses special computer software that controls the device, which minimizes the risk of error.

CNC turning is a process of separating the outer and inner layers of the material from the object in the shape of a rotating body using a turning knife. In this way, the desired shape of the product is created. This method allows us to obtain highly accurate products in various forms in a reasonably short time. It’s advantage is the ability to quickly reproduce the same product in huge quantities.

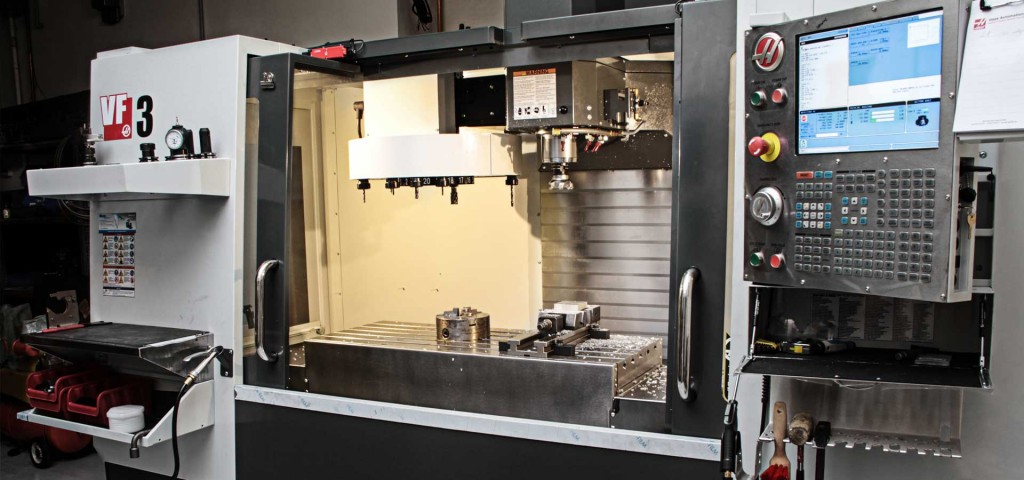

CNC MILLING

CNC milling is a type of chip machining. It allows processing of channels, planes, grooves, teeth and shaped surfaces. A milling machine moves in a rotary motion, while the sliding movement can be performed by either the tool or the workpiece. Thanks to this method, very complex shapes of materials such as metal, plastic and wood can be very precisely and quickly obtained. CNC milling is great for industrial production. It produces a large number of products of the same shape.

|

|

|

|

|

|

|

|

|

PL

PL  EN

EN